V4 Chapter 32

Details

179. 2009-01-26 Antenna Pointing Error

I have been spending a lot of time attempting to find a pointing error in the antenna. The problem is that the antenna is very accurate in the first 90 degrees of elevation but after traveling into the second 90 degree area it will 'loose its way' coming back. Its off as much as 40 degrees and needs to be homed every time. At this point I don't know if its a mechanical error (some non-vertical component of the mechanical stuff) or, more likely, some dumb software bug put in by yours truly.

I am also burned out looking for it and might put aside for a while.

2009-02-09 I think I'm getting close to the problem. This is what I did:

- Went over every line of the software. I found lots of improvements but nothing that would cause this problem. I even toyed with the idea of making the calculations different moving up from down but that would simply have hidden the problem (bad idea).

- Verified that moving positive had a different counts/degree than moving negative by repeated movement

- Verified that the problem was local to elevation - azimuth works fine

- Swapped out the elevation PIC controller. New one works fine so its not the logic on the controller

- Looked at the phase A and B signals coming out of the elevation encoder. Phase A looked fine but phase B was to narrow.

- Replaced the Hall Effect IC's on the encoder.

- First time around I forgot to add the pull up resisters (3.9K). Looked good on the 'scope.

I'm now waiting for the wind and rain to die down so that I can replace the encoder on the motor.

Elevation Motor Encoder

The two IC are DIODES Inc AH337

The pc board was the one used on the old SETI Net rotor motor. It was designed many years ago when Hall Effect devices required a lot of support chips (Op Amps) but mechanically the board fit so it was reused. I had to flip HA over to get it closer to 90° fro HB. It seems to work fine.

2009-02-16

- Well replacing the encoder did NOT fix the problem but I did finally find the

problem - The gears on the damn rotor are stripped. When I would move the

antenna up the extra load on the motor (gravity) causes the worm gear on the

motor shaft to jump teeth on the next gear in the chain. This is a serious

problem as that motor is not a common type and will be hard to find parts for

it.

2009-02-16

- Well replacing the encoder did NOT fix the problem but I did finally find the

problem - The gears on the damn rotor are stripped. When I would move the

antenna up the extra load on the motor (gravity) causes the worm gear on the

motor shaft to jump teeth on the next gear in the chain. This is a serious

problem as that motor is not a common type and will be hard to find parts for

it.

The good news is that the motor can be removed from the antenna easily. The old system required that the whole antenna be removed from the rotor and then the rotor removed, lugged down to my workshop (90lbs) and the case removed to get at the motor. On this system its simply three bolts and out it comes.

I did find and buy a right angle drive motor at the local surplus store but it seems lighter than the one that is stripped. Looking at the mount it may be possible to mount a tough Oriental Motor gear box on the same plate and have the motor mount to that. It would not be a right angle drive but it looks like it might clear anyway.

Hope springs eternal.

Until I decide what to do I can continue to use the system so long as I don't have to move the elevation a lot.

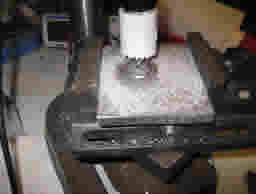

Stock Motor with Stripped Gear (Valeo 404.854 from NetMotion)

2009-02-24 Replaced the Motor - I decided to replace the stock motor (above) with the motor from my old rotor. This motor is not a right angle drive so I had to build a transition plate to pick up the mounting holes on the antenna and the holes on the motor. The following show the construction of the plate and attachment to the rotor mount.

Transition

Plate on the Whittling table Transition

Plate on the Whittling table |

Motor Mounted to the plate Motor Mounted to the plate |

|

A test of the motor from the local control box shows that it works fine.

The new motor has a shaft out the rear that I use to attach the encoder. This turns much faster than attaching the encoder on the output of the gearbox the way it had to be done on the old motor. With this arrangement I expect approximately 100,000 encoder counts for 180° movement much more than the 3,000 or so counts from the old system. This way if I miss a count or twelve because of noise in the system it won't change the calculations much (how's that for being scientific).

2009-02-25 - Finally solved the problem. The new motor works great and the encoder does it job as well. You can't ask for much more than that. A complete movement from +6° to + 172° generates 447,727 pulses and is very repeatable. Now I can finally get on with it.

Encoder Mounted on Motor Shaft

178. 2009-01-21 Look Around

At this point I have the SETI side of the station running reasonable well with a few problems remaining. The attention needs to be placed on the Radio Astronomy side now. This is a short look around of things to do

-

Antenna crashes into 180 degrees Az and thumps it's head - Sounds like a software problem

-

Add fourth Kerr controller to the system. This will be used to control the power to the noise source.

-

RA receiver needs to be modified to stop supplying power to the LNA - Might be as simple as a cut with the X-acto blade

-

Antenna Az/El needs to be calibrated and possibly the rotors plumb lined - Bothersome (no ideas)

-

Start on Client/Server system - Resurrect the old one and see if it still works

-

I would like to open up the video server (9100A) and see if I can see an analog audio filter that I can defeat.